Supporting industrial operations since 1978.

We combine our long-standing experience in electric motor rewinding and industrial overhauls with a commitment to timely service, ensuring our experts quickly pinpoint and resolve your operational challenges.

Providing solutions to significantly reduce costly downtime

A breakdown of our shop's services

AC motor services offered

- Dismantle and Inspect motor

- Replace bearings

- Sandblast parts

- Surge Test windings

- Meg the windings

- Hipot windings

- Test all the protection devices in the motors

- Overhaul brakes

- Rewind stators

- Rewind to class H

- Redesign windings to 2 speed

- Change the windings to different voltage

- Rewind and overhaul single phase motors

- Rewind brake coils

- Dip and bake windings

- Epoxy/waterproof windings

- Convert TEFC to TEAO

- Extend lead wires

- Machine works

- Replace couplings/pinions

- Resleeve Bearing housings/ journal

- Modification in the shaft

- Overhaul or replace gearboxes

- Overhaul pump motors

Services for DC motors

- Test Electrical and mechanical conditions

- Surge test the stator

- Clean the equipment and sandblast parts

- Replace bearings

- Test stator and armature separate

- Inspect brushes, brush holders and commutator

- Set neutral point

- Rewind armature

- Rewind field and compensating windings

- Dip and bake the stator and armature

- Balance armature

- Machine and undercut commutator

- Modify brush/ brush holders/ post

- Replace bearings

Services offered for slip ring induction motor

- Test Electrical and mechanical conditions

- Surge test the stator

- Clean the equipment and sandblast parts

- Replace bearings

- Inspect brushes & brush holders

- Inspect slip rings and machine it if needed

- Dip and bake windings / armature for better insulation

- Strip & rewind stator or armature

- Balance armature.

- epoxy spray windings

- Replace pinion / pulleys if needed

- Repair damaged lead wires

- Modification work in the motor if requested by customer of to fit the application

- Replace brushes

- Make new keys /gasket

- Test run at full voltage and speed without load

Crane motors

- Test Electrical and mechanical conditions

- Remove brake and inspect it

- Surge test the stator

- Clean the equipment and sandblast parts

- Replace bearings

- Rewind motors

- Remove and reinstall pinions

- Test eddy current and rewind them if found faulty

- replace couplings if needed

- Rewind the stators 2 speed

Main Test panel

Designed and built entirely within our shop, our test bench facilitates testing of 300HP AC and 150HP DC motors, along with thorough winding evaluations.

Surge tester

Our surge tester ITIG II is a portable, comprehensive winding analyzer used for testing electric motor and coil insulation. It combines multiple tests like surge, resistance, and hipot into one device, allowing for accurate fault detection and preventative maintenance.

Baking oven

Designed for thermal processing, our oven reaches up to 380°F, enabling us to preheat windings, cure varnish after dipping, and efficiently dry wet stators and armatures.

Winding machine

Engineered for precision, our winding machine constructs coil forms for motors reaching up to 300HP AC motors. Utilizing a suite of forming dies, we make coil forms for armatures, field coils, compensating windings, and brake coils with engineered precision and maximum efficiency

Parts washer

We utilize a 15 HP pump-driven parts washer for omnidirectional cleaning, effectively removing contaminants from all surfaces, ensuring equipment returns perfect.

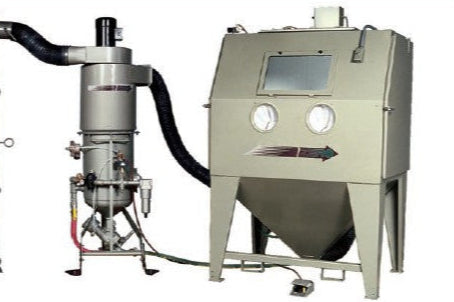

Sandblaster

Our sandblasting process uses high-pressure aluminum oxide to strip paint, rust, and other impurities from metal, leaving a thoroughly cleaned surface

Lathe

We offer complete machining services on our lathe, capable of custom product modifications and precise replication of existing parts to meet specific client needs.

Milling machine

To achieve intricate part modifications that require precise movements across all three axes, our milling machine and lathe operate in a coordinated workflow, each contributing its specialized capabilities.

CC-1105

DOLPHON CC-1105 is a solventless polyester resin which we use as an electrical insulating varnish. It offers high bond strength, low VOCs, and good penetration, making it suitable for various applications like motors, transformers, and coils.